Transportation technology

Technology of carriage of lumber

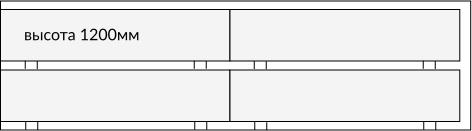

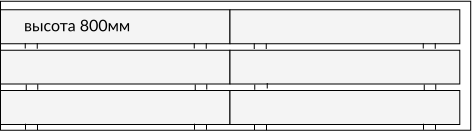

We recommend using the following package heights: 800 mm (for 3-layer loading) or 1,200 mm (for 2-layer loading). 800 mm packages withstand transportation and handling better; in many countries of the world, they became the packing standard.

The package width should be 1.12 m maximum, which guarantees safe container loading. When lumber packages of the same type are loaded, their length should have a negative allowance. For example: in case of loading into a container 6 m packages, the material should be trimmed to 5.98 m, with 4 m packages - 3.98 m, with 3 m packages - 2.98 m.

To prevent packages from breaking during reloads and transportation, we recommend using an increased number of fixing tapes - one per meter of length minimum.

Each package is marked at least on 2 sides (1 end mark and 1 side mark), preferably on 4 sides (2 end marks and 2 side marks). A marking table should be made of water-repellent material and contain the following data*:

- Package number (the package number should be unique across the shipping batch, i. e. identical numbers are not allowed in different cars)

- Plank section and length

- Material species

- Package volume (nominal)

- Humidity

- Grade

*Material marking requirements can be set or amended by contract provisions.

Package arrangement:

Lumber package arrangement is the key parameter determining a container's loading capacity.

Proper package formation secures full and maximum container loading.

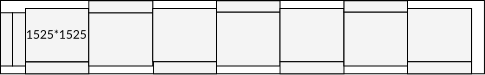

General information and guidelines for the preparation of veneer for carriage

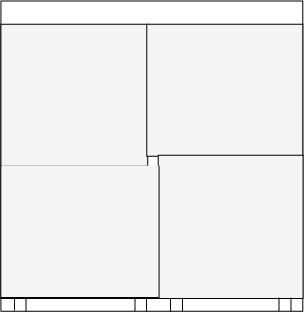

The most important requirement when it comes to transportation of veneer sheets is moisture protection. Veneer sheets are handled in indoor storages only. To maximize a container's loading capacity, veneer bundles should form a dense package with a strong crate. The maximum use of a container's loading capacity is achieved by forming optimum packages or by placing the packages both horizontally and vertically.

General information and guidelines for the preparation of plywood for transport

The most important requirement when it comes to transportation of plywood is moisture protection. Plywood is handled in indoor storages only. Containers for plywood are checked for leaktightness before loading. Plywood is transported both in 20- and 40-foot containers. The maximum use of a container's loading capacity is achieved when plywood is transferred in 40-foot containers.

Given the wide variety of plywood size types, there are numerous schemes of allocating this cargo in a container. We provide allocation schemes for the most common plywood formats: 1,525 * 1,525 mm, 1,220 * 2,440 mm, 1,830 * 1,525 mm